This post is also available in:

- Polymer-Modified Formula

- All-purpose Mortar

- Good Bond Strength

- Extended Open Time & Reduced Slip

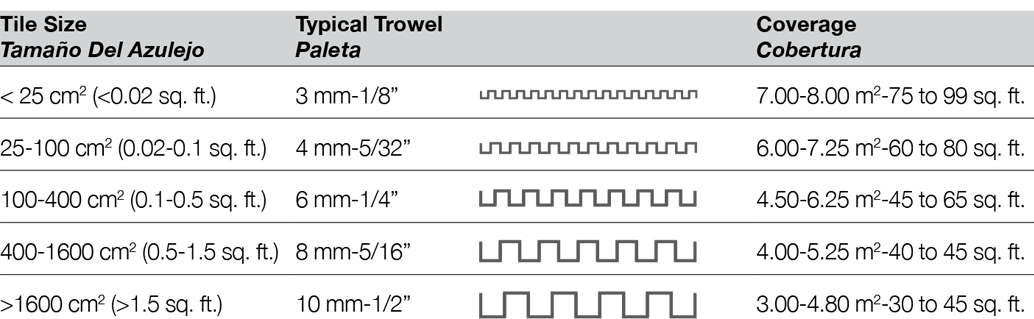

A polymer-modified formula, all-purpose mortar, to provide good bond strength for floor and tile projects. ECOVOX 101X cures quickly and adheres to most surfaces.

Key Features

For basic installations, economic yet strong.

Bonds to cement and exterior-grade plywood surfaces.

Suitable Tile Types

Extended open time and reduced slip & Cures quickly.

Ceramic, mosaic, quarry, cement body tile & Brick and thin brick.

Concrete, mortar beds, masonry, Portland cement plaster.

Exterior Grade Plywood (interior residential and light commercial dry areas).

Gypsum wallboard (interior dry areas) & Existing ceramic tile (scarified).

Plastic laminates (scarified) & Cutback adhesive (see preparation instructions).

Surfaces treated with Surface GripVox Primer.

Limitations to the Product

Do not bond directly to hardwood, Luan plywood, particle board, parquet, cushion or sponge-back vinyl flooring, metal, fiberglass, plastic or OSB panels. Not recommended for

interior and exterior pools and water features. Do not use to install resin-backed stone. Surfaces to be tiled must be structurally sound and subject to deflection not to exceed the current ANSI Standards. Substrates must be sound, free from oil, grease, and sufficiently dry. Cementitious substrates must be cured. Plywood flooring including those under resilient flooring must be structurally sound and meet all ANSI and deflection requirements. Ambient temperature should be maintained above 50° F (10° C) or below 100° F (38° C) for 72 hours to achieve proper bond. Expansion joints must be installed in accordance with local building codes and ANSI/TCNA guidelines. Refer to TCNA EJ171. Plywood floors, including those under resilient flooring, must be structurally sound and must meet all ANSI A108.01 Part 3.4 requirements. Maximum allowable deflection: L/360 tile L/720 stone. See TCNA F150-13 Tile Installations, TCNA F141-13 and F250-13 for Stone.

Curing of Product

Curing time is affected by ambient and surface temperatures and humidity. Use the following as a guideline. Allow 24 hours before grouting and light traffic, and 7-10 days before heavy or vehicular traffic.

Applicable Standards

American National Standards Institute (ANSI) — ANSI A108.5, A118.4 and A118.11 of the American National Standards for the Installation of Ceramic Tile ASTM International (ASTM)

| Property | Test Method | Requirement | Typical Results |

|---|---|---|---|

| Pot Life | 4 Hours | ||

| Open Time | A118.4 Section 5.3 | > 20 minutes | Pass |

| 4 Week Shear Bond Strength | |||

|---|---|---|---|

| Glazed Wall Tile | A118.4 Section 5.1.5 | > 300 psi | 450-550 psi (31.6 38.7 kg/cm²) |

| Porcelain Tile | A118.4 Section 5.2.4 | > 200 psi | 300-400 psi (21.1 28.1 kg/cm²) |

| Quarry Tile to Plywood | A118.11 Section 4.1.2 | > 150 psi | 150-250 psi (10.5 17.6 kg/cm²) |

TR

TR  ENG

ENG